Intermediate frequency induction heating power supply is used for induction heat treatment (quenching, annealing, tempering) of various metal materials and hardware tools, mechanical parts, partial or overall heat penetration, smelting, hot forging, hot upsetting, brazing and sintering, etc.

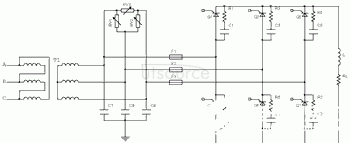

Early SPWM intermediate frequency power supplies were mostly composed of discrete components. The oscillator, comparator, dead-zone generator, drive, etc. in the system needed to be carefully adjusted, and the reliability was not high. Now this kind of scheme is rarely used; The monolithic integrated SPWM controller, such as HEF4752V, integrates the oscillator, comparator, operational amplifier, etc. into the monolithic IC, which greatly simplifies the system design and greatly improves the system reliability; with high-speed single-chip microcomputers and low price With the advent of DSP, digital intermediate frequency power supplies began to be widely used. At the same time, programmable digital SPWM generators, such as SA83, have emerged, which further simplifies system design and improves system reliability. However, all these control schemes require at least three isolated power supplies when forming a complete power supply system, and it is difficult to further reduce the power supply volume. Therefore, a three-phase fully-controlled bridge rectifier circuit based on the TCA785 chip is developed as an intermediate frequency power supply. The main circuit principle is shown in Figure 1, and it has received good results in field use.

Figure 1 Schematic diagram of three-phase fully controlled rectifier bridge circuit

Introduction to TCA785 Phase Shift Trigger

TCA785 is the third-generation thyristor monolithic phase-shifting trigger integrated circuit developed by German Siemens. Compared with the original KJ series or KC series thyristor phase-shifting trigger circuits, it can identify zero points more reliably and the output pulses are more uniform. Good, and the phase shift range is wider, and because the width of the output pulse can be adjusted freely, the application range is wider.

The TCA785 chip is a dual in-line 16-pin large-scale integrated circuit. As shown in Figure 2, its pin 5 is the synchronous voltage input terminal. Different synchronous voltages can be connected through different resistors. When a 200kΩ resistor is connected, the synchronous The voltage can be directly connected to 220V. In the application, it is necessary to connect a protective forward and reverse parallel diode limiting circuit; pin 9 is the sawtooth wave resistor connection end, and the resistance value determines the charging current and lead of the capacitor C10 on pin 10. The voltage level of the sawtooth wave at pin 10 is in the range of 3~300kΩ; the pin 10 is the connection terminal of the sawtooth wave capacitor Cl0, and the application range is 500pF~1F; the pin 11 is the input terminal of the output pulse phase shift control DC voltage. When its effective range is continuously changing within 0.2V~(Vcc-2)V, the phase of the output pulse can be continuously changed between 0°~180°; pins 14 and 15 are output pulse terminals, and the two ends can output width changes, For pulses with a phase difference of 180°, the pulse width is controlled by the external capacitance of pin 12.

Figure 2 TCA785 chip

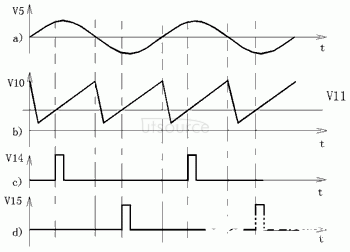

The input and output waveforms of several main pins of 5, 10, 14 and 15 are shown in Figure 3.

Figure 3 Input and output waveforms of some pins

The main parameters of TCA785 phase shift trigger include: power supply voltage 8~18V or ±(4~9) V, phase shift voltage range 0.2~(Vcc-2) V, maximum output pulse width 180°, maximum operating frequency 10~500Hz , The maximum load current is 400mA, the output pulse high and low level Vcc and 0.3V.

Comments

participate in discussions

Please login ? to participate in the comments

New customer Start here.